1、The first generation washing technology

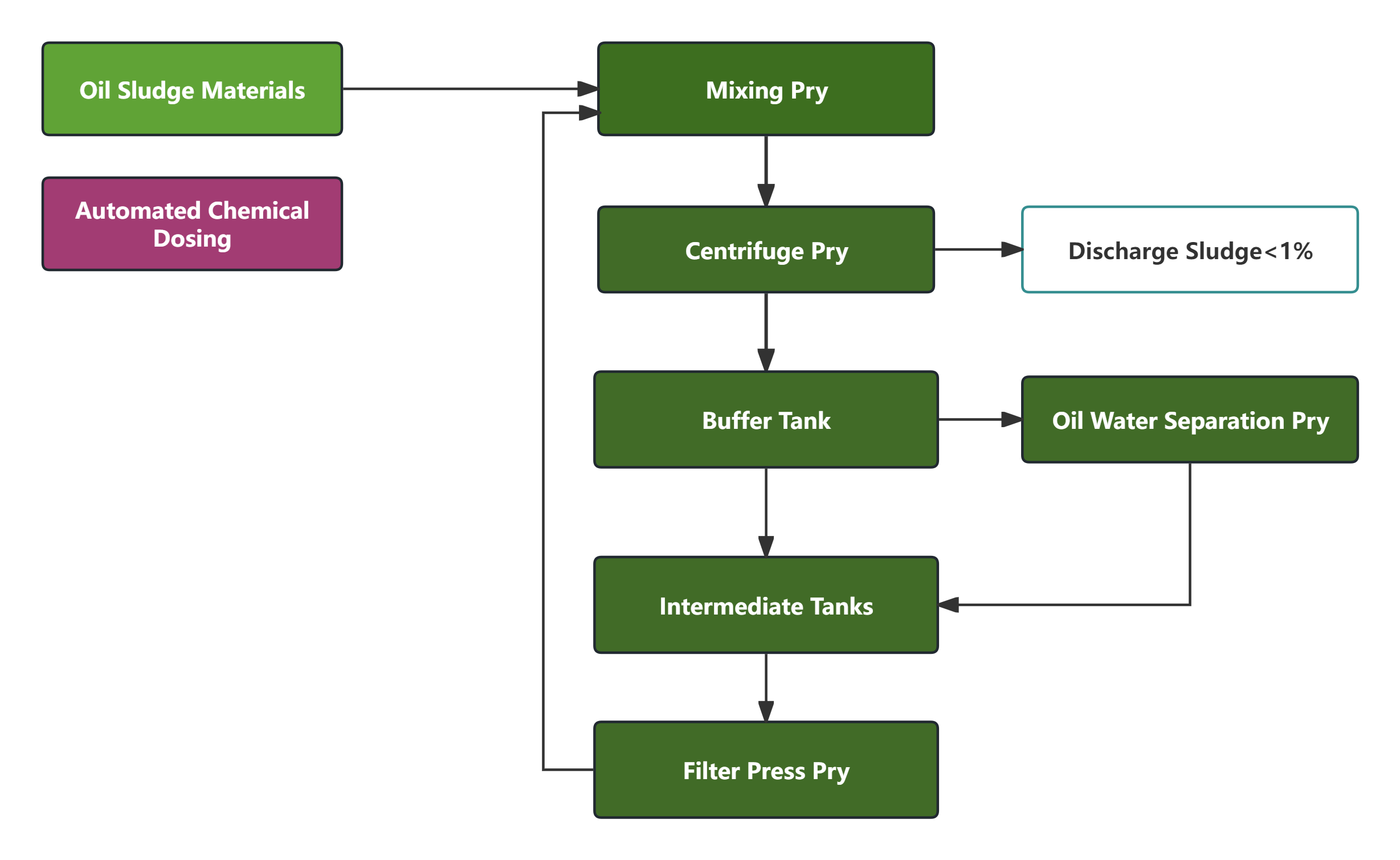

(1)Process flow diagram

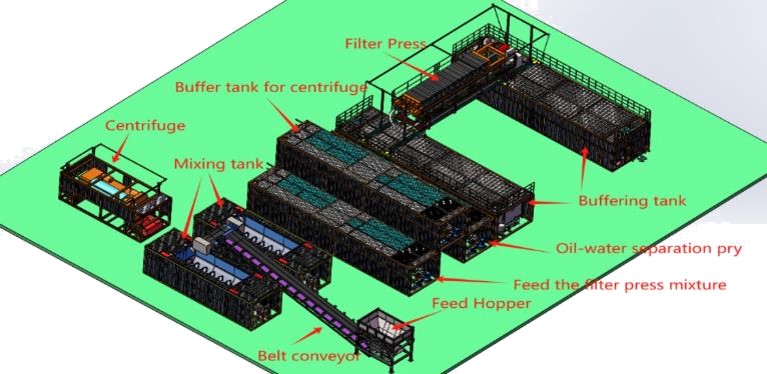

(2)The first generation washing system 3D view

(3) Equipment on-site photos(zone-2)

5 sets of equipment for co-production, with a total capacity of 500 tons/day

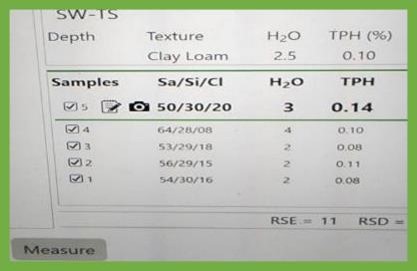

(4) Test

2、The second generation washing technology

ultra-large capacity, single set of equipment capacity 500 tons/days

(1) Overview:

ZAOPINST-KOCⅡ-type water washing system is an optimized scheme developed by ZAOPINST during the implementation of the KOC project. Compared to the original plan, the optimized scheme is expected to achieve a production capacity of 500 tons per day per unit of equipment. The equipment process is simpler, and after successful pilot experiments and tests, it is anticipated to have a profound impact on the remediation of KOC soil (water washing), accelerating the overall remediation progress.

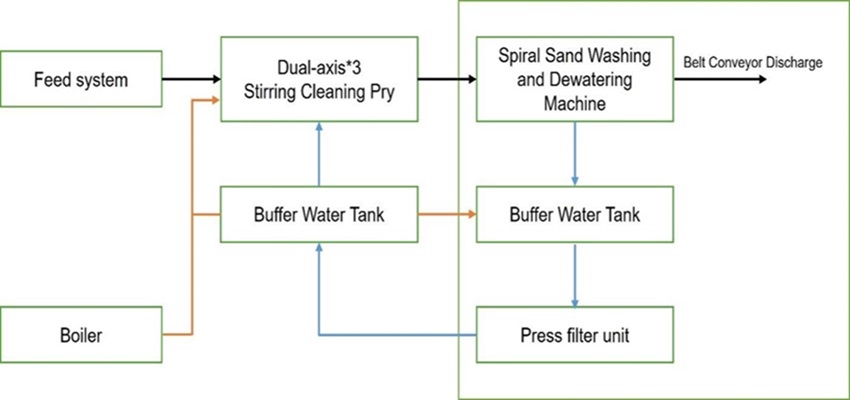

(2) Technological Process:

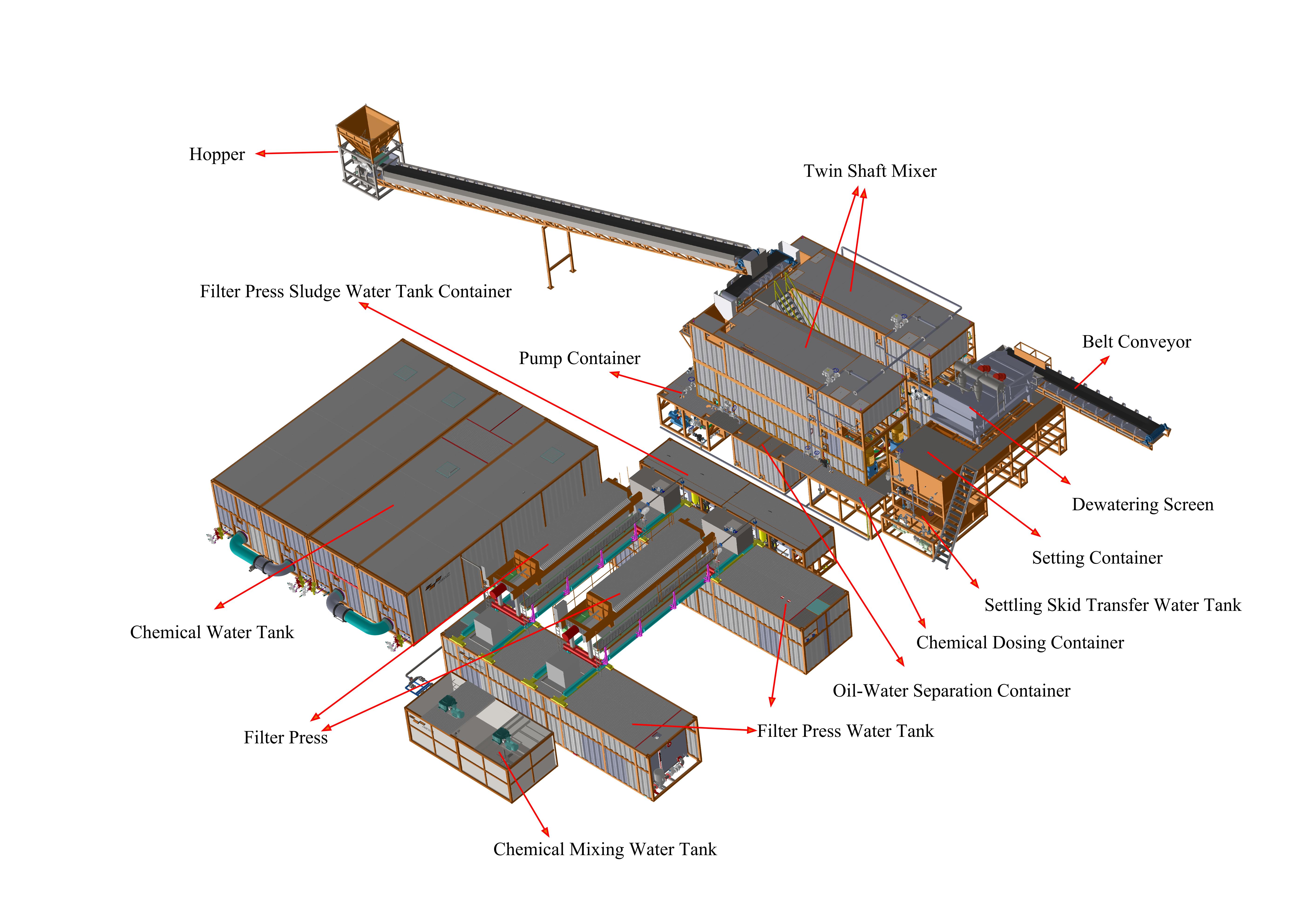

(3) The second generation washing system 3D view

(4) Process Description

The ZAOPINST-KOC II water washing system is primarily designed for the remediation of KOC petroleum hydrocarbon (TPH 5-10%) contaminated soil. Simultaneously, it can also serve as a pre-treatment design for highly oily lake sludge.

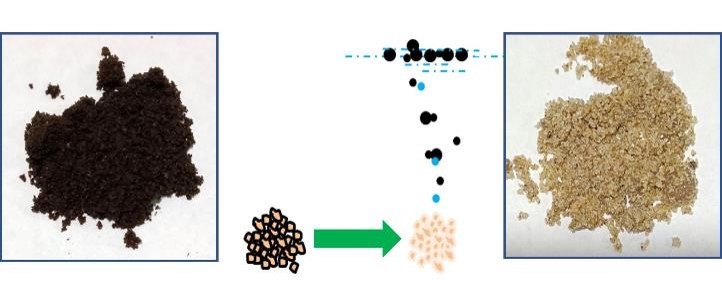

In the process of washing, under the action of cleaning agent and >85% temperature, oil that sticks to the sand will keep peeling away, then eventually gathers on the upper layer surface of the cleaning water. The slick will be performed oil-water separation when collected by slick collector installed on the cleaning skid, then the separated oil will be pumped to a storage tank, and the separated water will be returned to the cleaning skid.

Before washing After washing

Name: General Manager

Mobile:Wechat:+86 18857127993

Tel:+86 18857127993

Whatsapp:+86 18857127993

Email:zaopinst@gmail.com

Add:10th to 11th floors, Building 1, No. 398 Haida North Road, Xiasha Street, Qiantang District, Hangzhou City, Zhejiang Province