Crude oil washing system (COW)

Zaopin ST has the ability to clean the crude

oil storage tank series, refined oil storage tank series and the gas station

underground storage tank series. The company has established business

relationship with companies from 50 countries and regions, such as CNPC,

Sinopec for years, and has cleaned over 100 tanks with a cleaning tank volume from

30m3 to 100000m3. All cleaning machinery and equipment are

designed, developed and manufactured Zaopin ST, and all have obtained national

patents.

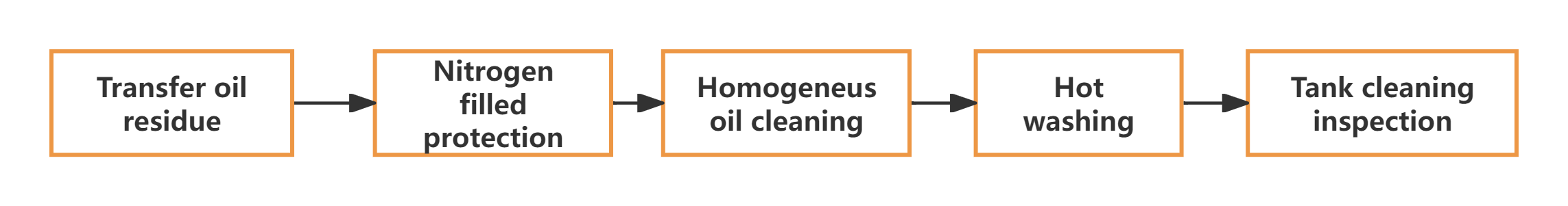

1、Process flow

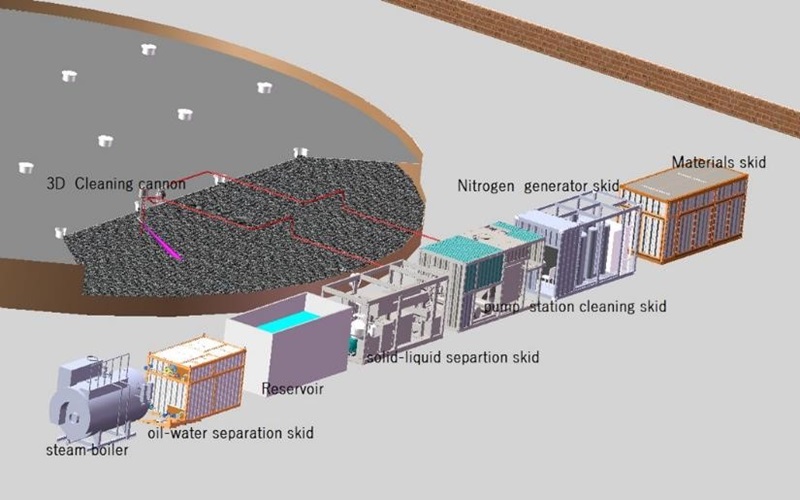

2、OWS 3D view

3、Oil-water separation

Zaopin

ST has the most advanced oil sludge separation technology in the industry, which

mainly consists of mixing homogeneous skid, centrifugal separating skid and

parameters.

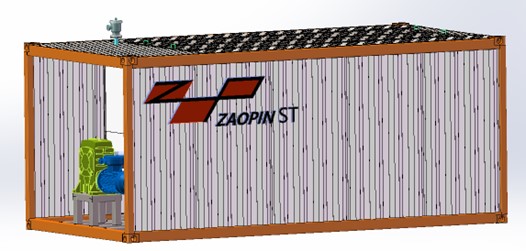

3.1 Mixing skid

(1)3D view

(2)equipment parameters list:

|

S/N |

name | model | Specification | Num. |

| 1 | Steam coil | ZAOPIN ST |

|

1 set/unit |

| 2 | Mixing shaft | ZAOPIN ST |

|

1 set/unit |

| 3 | Explosion-proof operation control box | BXK |

|

1 pc/unit |

| 4 | explosion-proof motor | YB3-160M-4-15KW | 15KW |

1 pc/unit |

| 5 | water tank | Effective volume 15 M3 |

|

1 pc/unit |

| 6 | converter | 15 KW |

|

1 pc/unit |

| 7 | thermometer | 0-200 C° |

|

1 pc/unit |

| 8 | reducer | WPDA250 | 1:30 |

1 pc/unit |

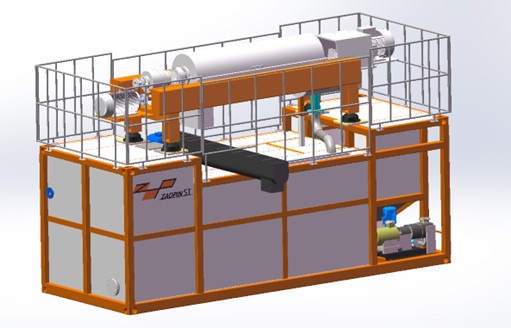

3.2 oil sludge separation skid

(1)equipment 3D

view:

(2)equipment

parameters list:

|

S/N |

Name |

Model |

Specification |

Num. |

|

1 |

Centrifuge |

750# |

120-37kw |

1 pc/unit |

| 2 |

Main motor |

YB3-250M-4 |

120KW |

1 pc/unit |

| 3 |

Auxiliary motor |

YB3-180M-2 |

37KW |

1 pc/unit |

| 4 |

Converter |

|

|

1 pc/unit |

| 5 |

Explosion-proof integrated power distribution cabinet |

BSG-T/XXL |

|

1 pc/unit |

| 6 |

Explosion-proof lightening (power)distribution box |

BXM(D)-T |

|

1 pc/unit |

| 7 |

Conveyer winch |

U300-total length 6000 |

3KW |

1 pc/unit |

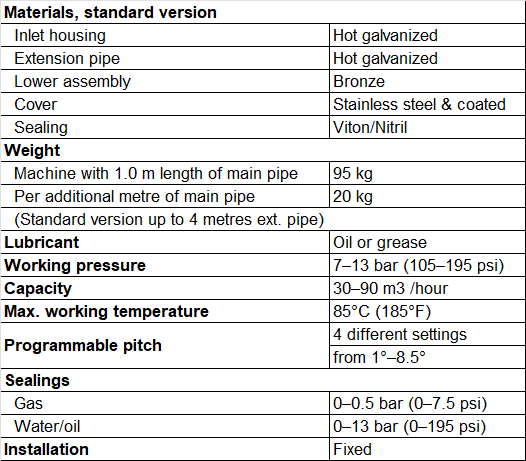

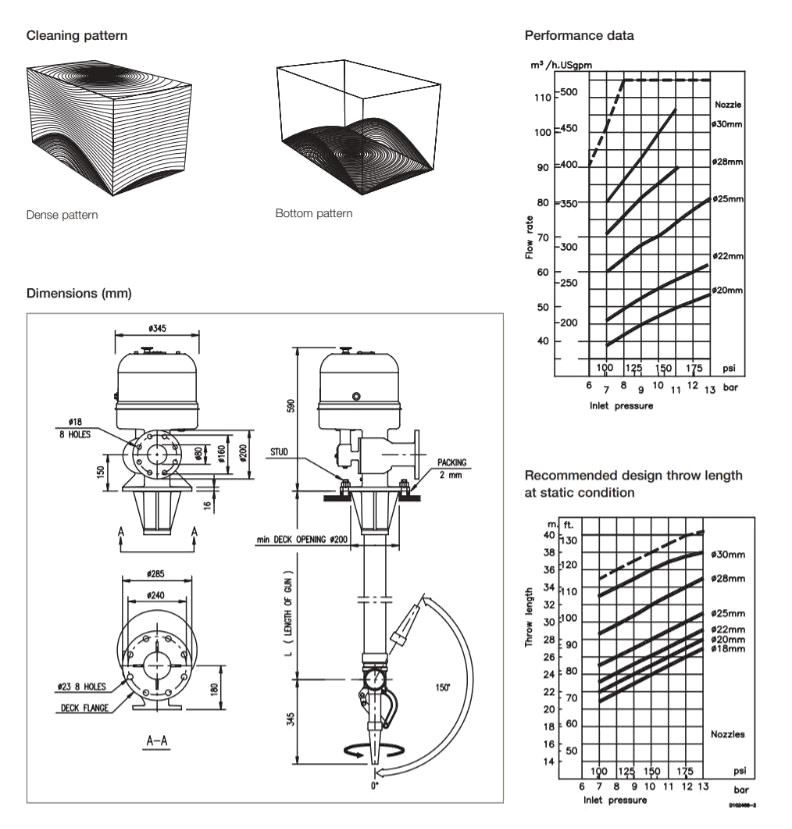

4、Tank top gun parameter introduction

4.1 Gunclean Toftejorg 270 FT Mark I

The Gunclean Toftejorg 270 FT Mark I is a fully programmable turbine driven single nozzle tank cleaning machine. Of all brands and makers the 270 FT is the most sold single nozzle tank cleaning machine for crude oil tankers and bulk carriers.

4.2 Options

•

Inlet flange according to JIS and ANSI standard.

• Deck

flange with customized dimensions.

•

Split extension pipe.

•

Sensor connection for all cargo control systems.

•

Capacity up to 115 m3 /hour.

•

Gasket & Sealings.

•

Strainer in flange.

•

Nozzle turning angle 170°.

4.3 Regulations

The equipment fully complies with IMO

regulations and the requirements of the classifications societies.

4.4 Specifications

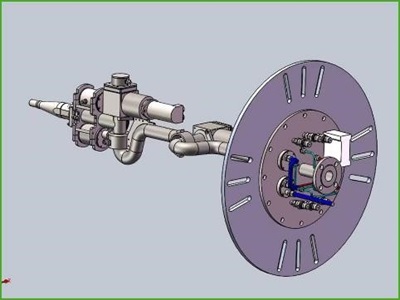

5、Sidewall (manhole) cleaning gun

Technical information:

(1) The cleaning gun is designed according to the requirements of ATEX/94/9/EG explosion-proof.

(2) The high pressure system is designed according to the requirements of TRBF20 (2002), and 1, 2 (2006) from TRBS2152.

(3) Single jetting gun is applicable to crude oil storage tanks with a diameter of 35m to ≤40m.

(4) With an automated technical process, the pressure jetting gun system of ZAOPIN ST can replace tradition manual cleaning approach that is high-risk, high physical and mental demanding.

(5) A single jetting gun is a unit that consists of one jet nozzle, one camera and one light source.

(6) The gun is installed on the tank’s manhole from the outside, and can be rotated 180° horizontally or vertically.

(7) Inside the tank, there are monitoring system and alarm system that can continuously monitor oxygen, flammable gases, hydrogen sulfide and carbon monoxide.

(8) The rotary drive adopts hydraulic transmission and is of high stability.

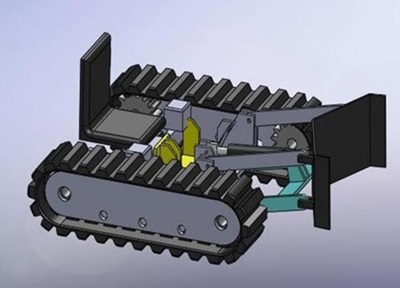

6、Cleaning trolley

For sludge that is particularly difficult to clean, the cleaning trolley installed inside, allowing manned/unmanned operations.

Hydraulic driven, crawler hub (carbon steel), steady grip. Structural parts are stainless steel.

(1)operation

Allow manual operation, manual real-time monitoring and unmanned operation.

(2)operator hand lever or computer joystick

With which the cleaning trolley can move forward, backward, turn left or right, etc.

Capable of operating additional actuator as well.

(3)additional actuators

a. high-pressure nozzle b. cleaning shovel c. front plane water jetting sweeping

(4) parameters:

a. high-pressure nozzle: maximum pressure 5MPA

b. cleaning shovel: vertical movement 300mm

c. front plane water jetting sweeping: spraying transverse distance 1400mm

d. length 1600mm, width 1200mm, height 800mm

(all parts can enter and exit the manhole smoothly, and the installation of the whole set of the cleaning trolley takes 2 hours.)

Name: General Manager

Mobile:Wechat:+86 18857127993

Tel:+86 18857127993

Whatsapp:+86 18857127993

Email:zaopinst@gmail.com

Add:10th to 11th floors, Building 1, No. 398 Haida North Road, Xiasha Street, Qiantang District, Hangzhou City, Zhejiang Province